한화 컨버전스 로고, 메인페이지로 이동

18449 7, Samsung 1-ro 3-gil, Hwaseong-si, Gyeonggi-do

TEL. 031-378-9731

FAX. 031-8003-9735

18449 7, Samsung 1-ro 3-gil, Hwaseong-si, Gyeonggi-do

TEL. 031-378-9731

FAX. 031-8003-9735

A factory automation solution that provides an automatic

facility operation concept based on automatically calculated values to provide

an environment optimized for the semiconductor manufacturing process

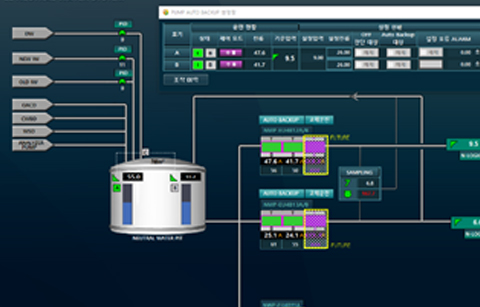

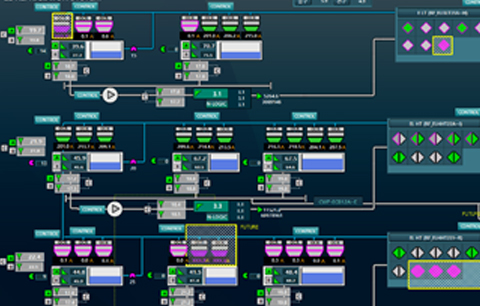

Real-time monitoring and control of all facilities supplying utilities in the plant

01

02

03

04

01

Automate the complicated process of discarding and resupplying it cleanly in the semiconductor/display manufacturing process when the circulating water sprayed in the exhaust scrubber is contaminated.*

* If the acidity (phexceeds or falls below the standard value)

Maintain production quality by automating switching to standby equipment in the event of a exhaust equipment failure during semiconductor/display manufacturing.

Maintain production quality by automating starting or stopping exhaust equipment under operation during semiconductor/display manufacturing.

02

Maintain production quality by automating starting or stopping cooling equipment under operation during semiconductor/display manufacturing.

03

Maintain production quality by automating switching to standby equipment in the event of a pump failure during semiconductor/display manufacturing.

04

Automate the thawing process by specifying groups and sequences and stop and run actions to prevent freezing of the cooling tower fan operating during semiconductor/display manufacturing in winter.

01

02

03

04

01

02

03

An integrated control system to monitor and control all facilities that supply utilities in a factory in real-time