한화 컨버전스 로고, 메인페이지로 이동

모바일 버튼

18449 7, Samsung 1-ro 3-gil, Hwaseong-si, Gyeonggi-do

TEL. 031-378-9731

FAX. 031-8003-9735

18449 7, Samsung 1-ro 3-gil, Hwaseong-si, Gyeonggi-do

TEL. 031-378-9731

FAX. 031-8003-9735

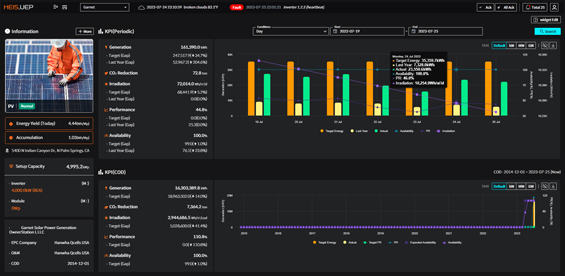

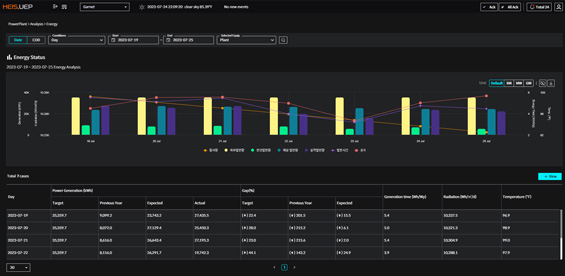

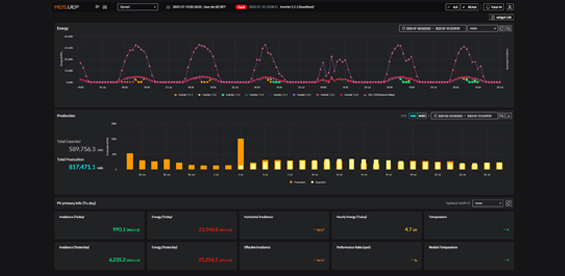

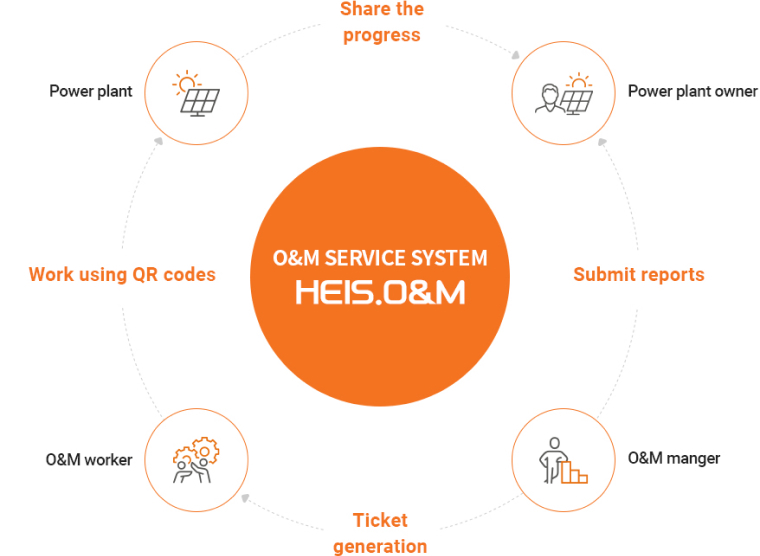

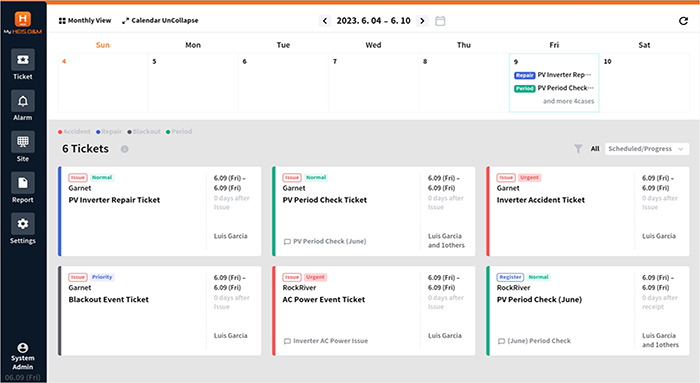

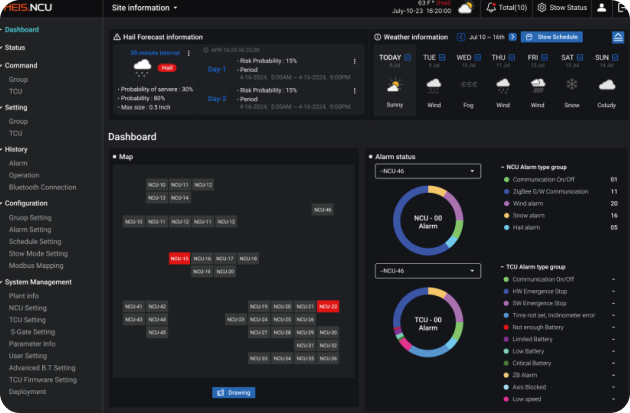

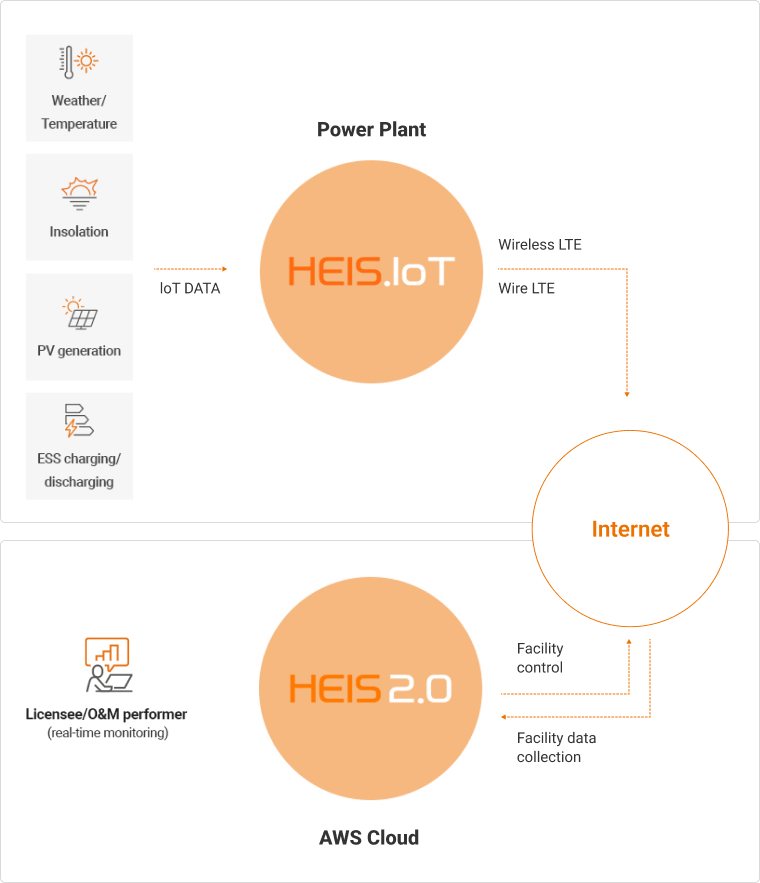

AWS cloud-based system

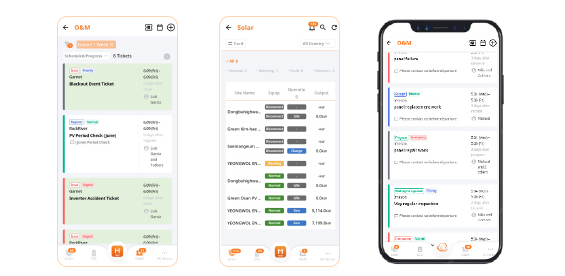

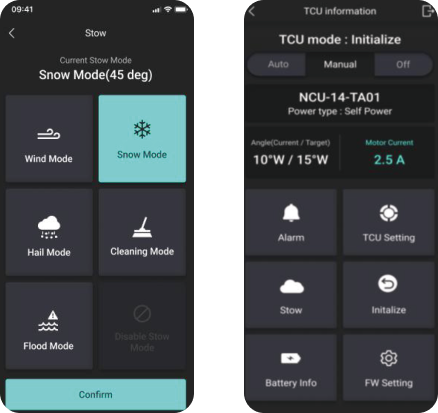

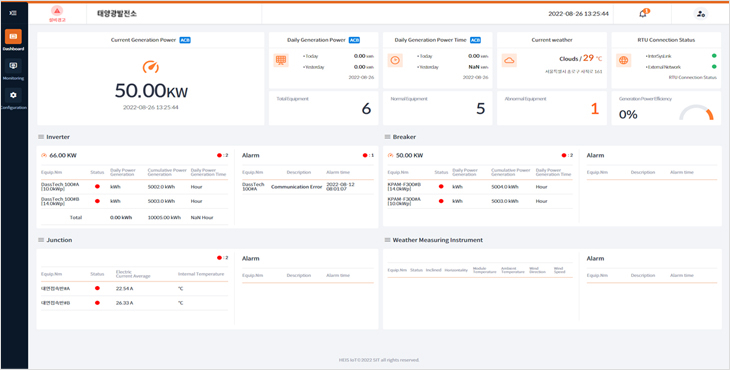

Mobile & PC web service

PC web service

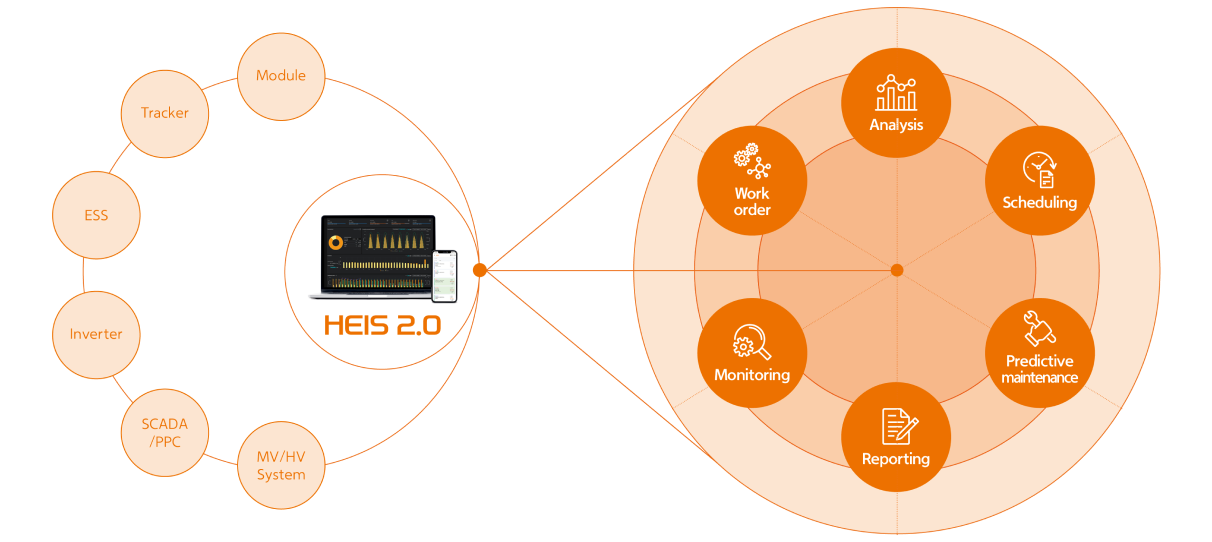

TCS: Tracker Control SysemPower Plant Data Acquisition System