한화 컨버전스 로고, 메인페이지로 이동

18449 7, Samsung 1-ro 3-gil, Hwaseong-si, Gyeonggi-do

TEL. 031-378-9731

FAX. 031-8003-9735

18449 7, Samsung 1-ro 3-gil, Hwaseong-si, Gyeonggi-do

TEL. 031-378-9731

FAX. 031-8003-9735

A factory automation solution that provides the best safety,

environment, and quality by efficiently monitoring and controlling various elements of the

factory environment necessary for the manufacturing process

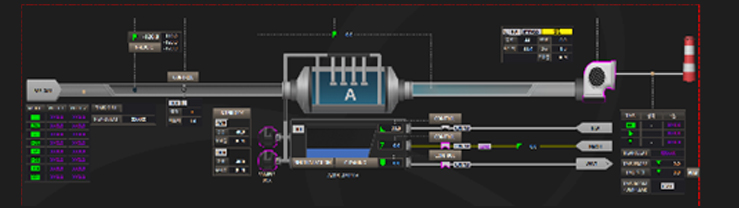

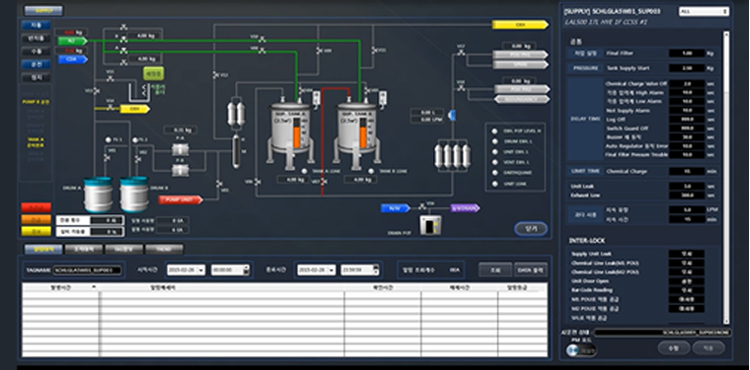

Real-time monitoring and control function for all utility-supplying facilities in the factory

01

02

03

04

01

Monitoring and control of various facilities that create optimal conditions such as temperature, humidity, air circulation, and cleanliness for the manufacturing process

(semiconductor, display, solar power, secondary battery, biotech, F&B, etc.)

02

Monitoring and controlling various facilities to manufacture and supply pure water used in the manufacturing process and wastewater treatment facilities to safely treat different types of sewage/wastewater generated during product production

(semiconductor, display, solar power, secondary battery, biotech, F&B, etc.)

03

Real-time monitoring of the power supply status in the factory and remote control of various power facilities to supply uninterrupted power

04

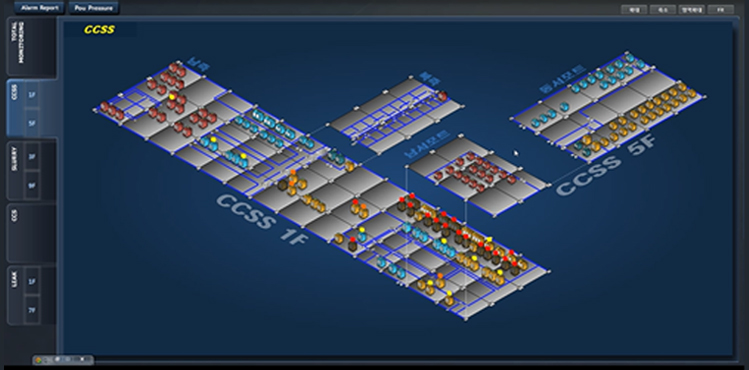

Efficient operation by collecting real-time information on various gas & chemical supply equipment required for factories

01

02

03

04

01

02

03

A factory automation solution that provides the best safety, environment, and quality by efficiently monitoring and controlling various elements of the factory environment necessary for the manufacturing process

A solution that supports the operation of a smart factory by realizing a factory in a virtual space

A data relay solution that collects data from manufacturing sites and integrates it by providing to upper IT systems (EES, ERP, MES, etc.) through a standardized method

A solution that monitors the infrastructure (server, OS information, network, DB, etc.) and process resource information (PLC, HMI) necessary for factory operation and informs the operator in case of an abnormality to take quick actions

An editing solution for HMI client program files

A solution that provides a reliable factory operating environment by preventing operator errors and implementing automatic operation conditions during facility operation

A solution to automatically implement panel/IO design drawings

A solution to secure product consistency by automating S/W testing

A solution for determining the number of days until the next maintenance, the optimal maintenance interval, the optimal maintenance action recommendation, and the possible cause of the failure

An integrated control system to monitor and control all facilities that supply utilities in a factory in real-time

Environments and experiences identical to the actual factories by realizing the work status/history of each process up to the finished product, facility performance, and sensor information in 3D

Smart factory infrastructure by realizing standardized system integration through data collection and relaying between other models