한화 컨버전스 로고, 메인페이지로 이동

18449 7, Samsung 1-ro 3-gil, Hwaseong-si, Gyeonggi-do

TEL. 031-378-9731

FAX. 031-8003-9735

18449 7, Samsung 1-ro 3-gil, Hwaseong-si, Gyeonggi-do

TEL. 031-378-9731

FAX. 031-8003-9735

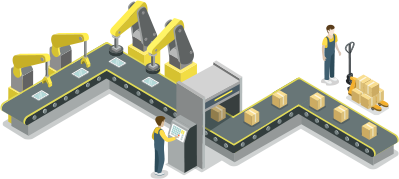

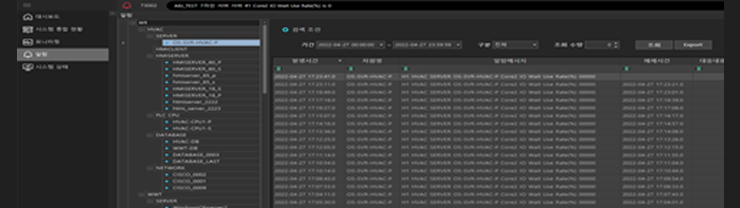

A solution that monitors the infrastructure (server, OS information, network, database, etc.)

and process resource (PLC, HMI) information required for factory operation and

informs the operator in case of an abnormality to take quick actions

Monitoring the status of infrastructures such as servers, HMIs, and PLCs in the factory and detecting abnormal conditions.

HVAC

WWT

UPW

ELEC

HMI

PLC

Server

Database

01

Real-time monitoring of factory infrastructure facilities

02

FIMS monitors the status of process resources (PLC, HMI) and infrastructure within the plant and generates an alarm

for operators to respond quickly when an abnormality is discovered.

01

02

01

02

A factory automation solution that provides the best safety, environment, and quality by efficiently monitoring and controlling various elements of the factory environment necessary for the manufacturing process

A data relay solution that collects data from manufacturing sites and integrates it by providing to upper IT systems (EES, ERP, MES, etc.) through a standardized method

An integrated control system to monitor and control all facilities that supply utilities in a factory in real-time

Smart factory infrastructure by realizing standardized system integration through data collection and relaying between other models