한화 컨버전스 로고, 메인페이지로 이동

18449 7, Samsung 1-ro 3-gil, Hwaseong-si, Gyeonggi-do

TEL. 031-378-9731

FAX. 031-8003-9735

18449 7, Samsung 1-ro 3-gil, Hwaseong-si, Gyeonggi-do

TEL. 031-378-9731

FAX. 031-8003-9735

A factory automation solution that contributes to better productivity

and improved quality of asset equipment by identifying the expected number of days

until the next maintenance, optimal maintenance intervals,

recommended optimal maintenance actions, and probable causes of

failure with a modeling-based predictive system.

The modeling-based predictive system contributes to better productivity and improved quality of asset equipment by identifying the expected number of days until the next maintenance, optimal maintenance intervals, recommended optimal maintenance actions, and probable causes of failure.

01

02

03

04

01

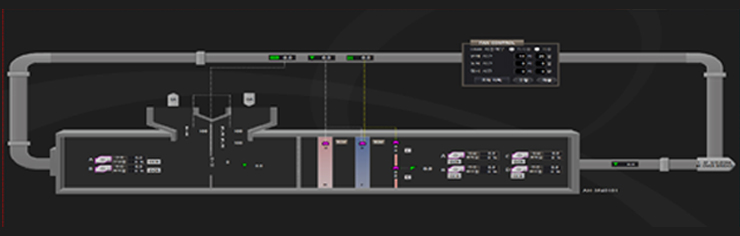

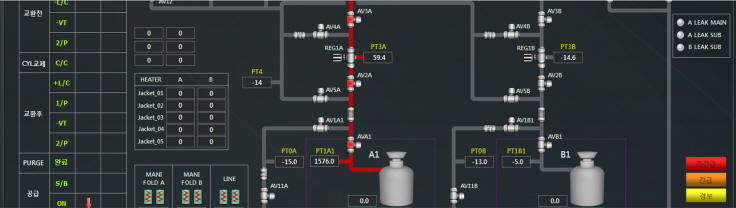

Foresee risks in advance by continuously monitoring and controlling air-conditioning facilities that create optimal temperature, humidity, air circulation, and cleanliness in clean rooms required for semiconductor/display product production.

02

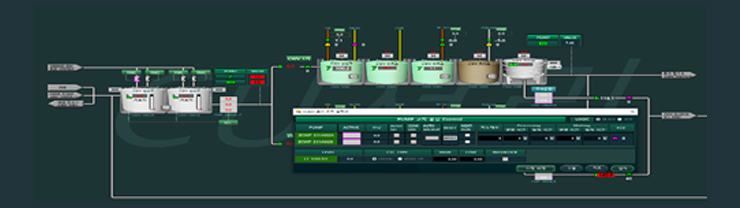

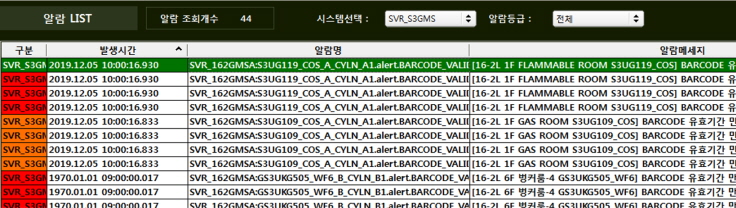

Monitor and diagnose sensor values (level, ampere, etc.) in real-time at the front and rear terminals of the operating facility, and notify the operator of abnormal changes. Identify failure factors of the operating equipment, operate the standby equipment to maintain the operating state, and prevent trouble in advance.

03

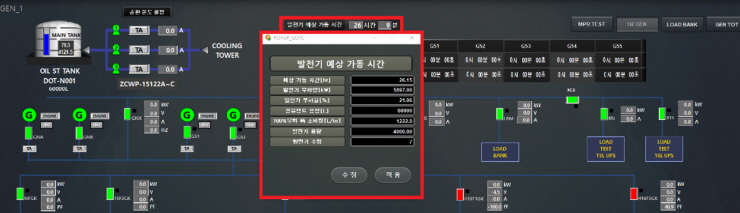

Calculate the UPS charge rate and the battery efficiency to predict the discharge time, and check the generator efficiency

and the amount of diesel to predict the generator's possible uptime.

04

Integrate and manage the expiry date information of various chemicals used in gas and chemical facilities to notify the replacement time

in advance and thereby providing chemical management safety and efficiency through.

01

02

03

04

01

02

03

An integrated control system to monitor and control all facilities that supply utilities in a factory in real-time